Superior technology has changed the view of world. Today very hard and tough metals can also bend and fold. There is a technique according to which companies first cut the steel, then bend it and then again join it. This technique is called steel fabrication and it is the best technique to form shutters. I think you must have seen the steel shutters in homes or on commercial spaces. These shutters are used widely because these are tough, durable and long running shutters. Today people are using things prepared through steel fabrication method and you must know this wonderful technique.

Things needed for steel fabrication:

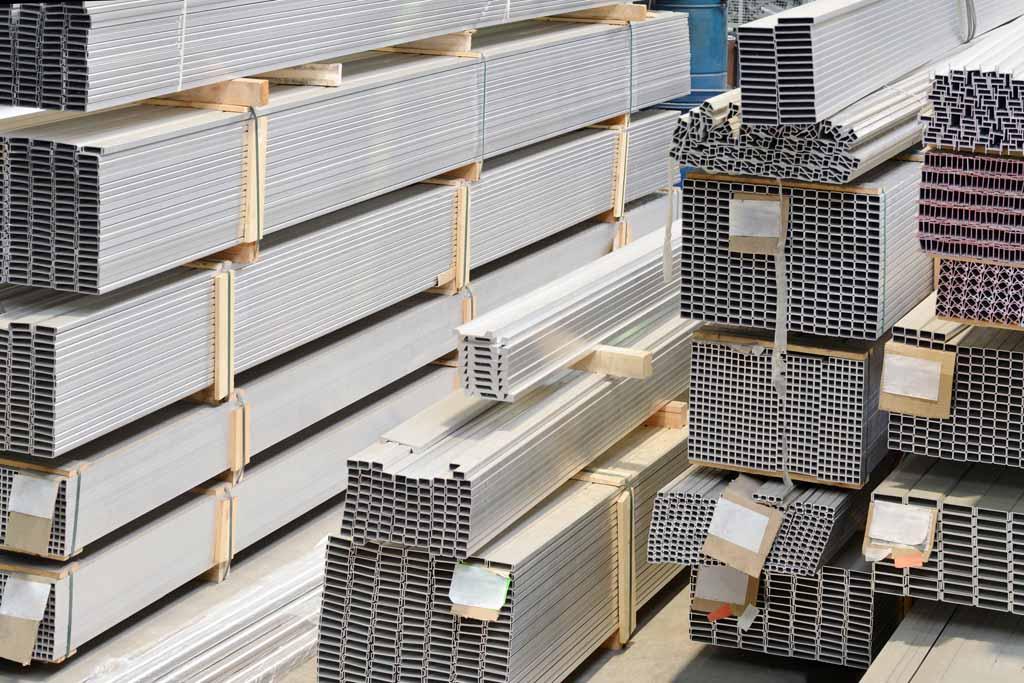

The method of fabricating steel is not so difficult to understand, but you must have idea about what raw material is required. Basically five things are needed in steel fabrication process. Because you are going to cut small pieces of tough metal, you will first need a plate metal. Another thing you will need is formed and expanded metal, tube stock, welding wire with rod and casting. The metal fabrication process gets completed by using these five important things. For welding people use aluminum welding rods with gas or with electricity.

Cutting the metal:

The first step you need to take for starting process of metal fabrication is cutting the metal. There are many metals, but steel is the best because it is the toughest metal. Before you cut the metal, you will need to decide the size of metal cuts. People do it for various purposes. If you are planning to have a new shutter, then simply do small cuts. People can also get the shutters for their home online. In steel fabrication process, first a metal plate is cut into size according to the thing the manufacturer wants to build of it.

Forming:

This is the second step in steel fabrication but it is one of the most important parts of whole process. Different kinds of objects are prepared through metal fabrication process. Before starting the process, manufacturers have idea about what object they are going to prepare. So the raw metal is deformed in a way that metal pieces can be prepared for manufacturing object. After cutting and deforming raw metal, parts are bended, and shaped according to object. For this force is applied on the metal piece in a way that metal can take a required shape.

Welding:

Before starting the welding process, the metal needs to go through machines. However, every steel fabrication shops do not apply this technique for manufacturing tough steel objects. Well, once metal is cut into perfect shape according to the object and formed in proper shape according to the requirement, then only welding process is left. For welding you just need welding wire and welding rods. Whole raw cut metals are welded carefully according to need of the object. Professional welders use protection glasses during welding to prevent their eyes from brightness of welding process.

Steel fabrication process has become very common now. Only because of this process various malleable metals are being turned into beautiful objects. From large steel tanks to small window shutters, all objects are being manufactured by using fabrication process. Metal fabrication has completely changed our world and it has offered us the toughest things to use. For home side use, steel fabrication process offers us durable shutters. These shutters serve longer and remain tough all their age. There are many other things prepared by using fabrication process. Today in large companies and also in small shops metal fabrication process takes place and many useful objects are being produced through this process. Steel fabrication industry occupies a major share in a country’s industrial and economic development as this industry provides job opportunities to many people.

If you want to know more than visiting this link you can get information about steel fabrication.

Bài viết liên quan

The Pros & Cons Of In-House Training For Your Business

When it comes to training, you’ve got a few options at your disposal. Everything needs to be taken into...

Buying a Horse: Some Common Mistakes

It is important when buying a horse that you choose one fit for your needs. It is no good...

How to Choose the Right Call Center Company to Handle Your Needs

Whether your company is big or small, call centers are a great way to handle the growing demand of...

Some Great Online Competitions to Be a Part Of

We all would love to win some cool gifts every now and then. Competitions are a great way for...

Want to Do Business in Another State? Here’s What You Should Know

While expanding your business into a neighboring state can be exciting, it can also come with legal complications if...

How Businesses Handle Seasonal Demand

Many businesses find themselves with increased demand during certain times of the year, especially in the lead up to...